BCA Leisure - West Yorkshire

Simon and Lee met with Wayne Boyd, Sales & Marketing Director of BCA Group, who showed us in detail the process BCA go through to ensure that we’re able to build our Bailey caravans and motorhomes to the modern standards we are so used to.

When it’s buried in a caravan or motorhome, you have no idea how much work, effort and design goes into a wiring loom. You might get in and turn on the lights, or boil the kettle… This visit gave us the chance to see the outstanding process involved into making all elements of a modern Bailey work.

SIMON: Wayne, you’re pretty much the one stop shop for all things electrical for Bailey caravans and motorhomes. How do you go about designing a wiring harness for a new Bailey leisure vehicle?

WAYNE: The process usually starts with 3D drawing of the new model from the Bailey design team, which we then flatten out to a 2D drawing so we can create a production pack.

SIMON: So I’m guessing the key factors would be the layout (where everything is in the vehicle) and also the specifications. For example, top of the range vehicles would have more electrical appliances, greater number of electrical comers, and consequently more wiring…

On the top of the head, what is the average length of a wiring loom in a standard Bailey caravan, or in this caravan (Pegasus Grande SE Ancona) to be more exact?

WAYNE: You would be looking at 160m for a 7m caravan. If you were to then put all those individual cables end to end, you would be looking at closer to 700m of cable per caravan!

SIMON: That must be a lot of copper… Is that the key component for BCA?

Yes, absolutely. Bailey consume about 2.5 tonnes of copper every month. With that in mind, for the amount of time we have been partners, we are looking on the region of 900 tonnes of copper.

SIMON: Other that copper, what else goes into a standard wiring harness?

WAYNE: There is the PVC that wraps around that copper and plastic products. Those are the core items we procure for Bailey and that’s what makes up most of your harnesses.

"If you put all the individual cables in a caravan end to end, you would be looking at 700m of wiring"

LEE: We are sat in a Bailey Pegasus Grande SE Ancona and Wayne has very kindly laid out a complete wiring loom of this caravan for us to park next to. I had no idea it was so complex. With that in mind, and with all the different layouts and components that might go into a modern Bailey Phoenix, Unicorn, Pegasus… how many looms do you actually have to manufacture for Bailey?

WAYNE: Looking at Bailey’s range of caravans and motorhomes, we would produce 1,100 wiring looms.

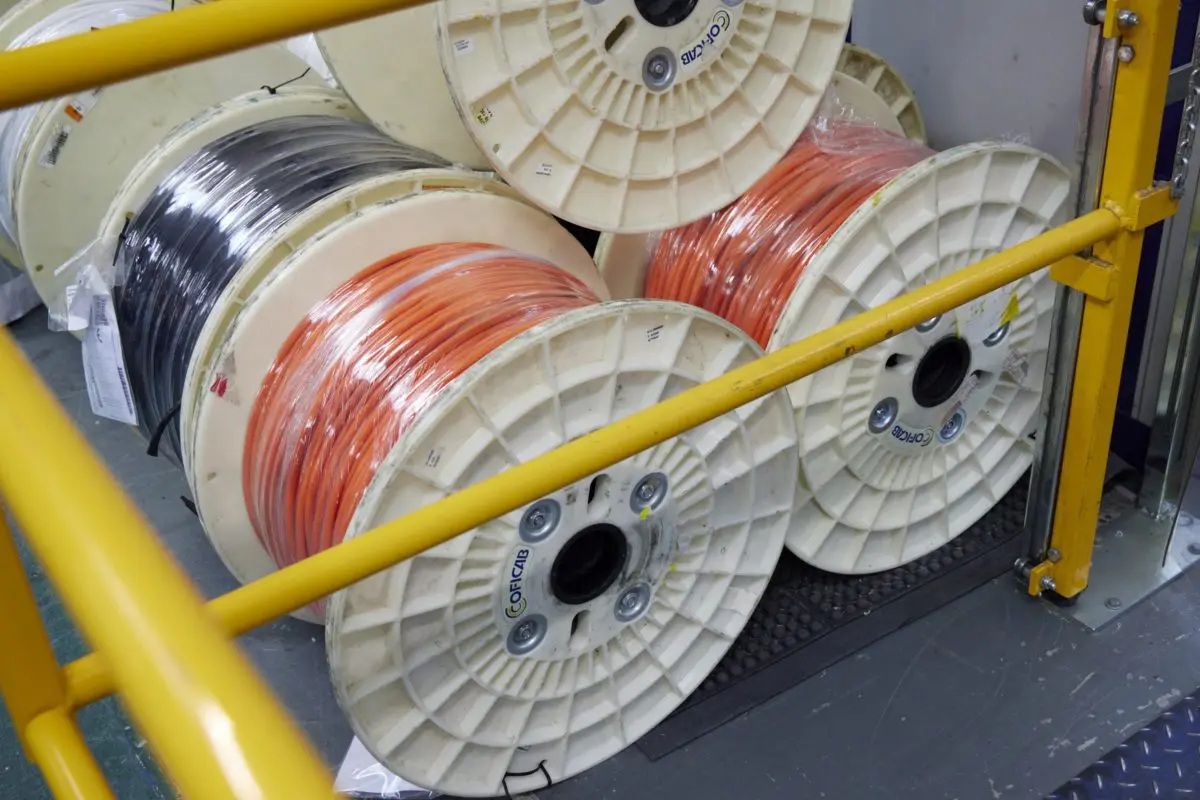

There is some commonality between for example your Pegasus and your Unicorn rear harnesses so we would produce them in bulk and keep these in stock. But when you’re building a kit size of, for example 50 off vehicles, that’s not something we have on the shelf. We have kilometres of cable sat in drums that we then produce for that set amount and would usually be sent to Bailey the week before production.

LEE: Talking about kilometres of cable… In length of looms, using the standardised measure of the Earth, how far would the amount of Bailey looms that BCA have manufactured for the last 30 years go?

WAYNE: The Bailey harnesses produced over the last 30 years would stretch 3 times around the globe!

SIMON: We had a quick look at the harness you have outside and certainly, we have come a long way from my dad’s times when Bailey would do the wiring in house with pin boards. But you do all that for us now and you really have added value to make it simple for us to assemble…

WAYNE: Yes. We have invested in some automotive machinery and we produce your harnesses in a number of ways. We still use those boards because some harnesses lend themselves to that construction method. But we also have those automotive machines that produce it right first time, every time and quality obviously is paramount.

SIMON: Do you need specialist electrical training to install your looms on the line at the Bailey factory?

WAYNE: What we have done to help with your production line, speed up processes and improve efficiency is to run a plug and play system. For example, when your operatives are fitting the 230v sockets to the cabinets on the line side, with our electrical harness they can just plug things in.

SIMON: That obviously speeds up the process and the accuracy. Less room for error when installing it. And you don’t need special electrical qualifications?

WAYNE: No. A competent person with the relevant amount of training can do it as you don’t have to open the socket. It’s all pre-wired within and ready to plug and play.

SIMON: Tell us a bit more about BCA. We are in the wonderful county of Yorkshire. How long has the business been in operation?

WAYNE: BCA was founded in 1981 in a village that is about 12 miles from here. We then moved to this purpose-built factory so we could have production facilities and logistics in one place.

SIMON: And how many people do you employ?

WAYNE: Across three sites there are 150 of us.

"In addition to caravans and motorhomes, we supply wiring looms for campervans, horse boxes, the amber light sector and decontamination trailers"

SIMON: So you supply for caravans and motorhomes. Are there any other markets you supply for?

WAYNE: Yes. We work in what is described as the amber light sector. These are for example the council vans with amber lights on the roof you see on the road. We supply harnesses for them to be able to convert a standard van into something that has those control systems in.

Likewise, we supply to horse box manufacturers, campervan converters and we also have a couple of customers that produce decontamination trailers. These are vehicles with an entrance and an exit that allow you to enter into the vehicle dirty, sanitise, wash and dry yourself and then leave through the exit door.

SIMON: Like most businesses I imagine you had to face up to the twin challenge of first Brexit and then COVID. Let’s talk about Brexit first. How has that affected your business?

WAYNE: If we consider both situations, Brexit came with a warning. We had some advance notice. So as a business we decided to bolster our stock holding in preparation. So we made that investment of an additional £2m worth of stock to ensure our customers had continuity of supply.

We then had other exit problems, logistically, like paperwork, etc, but we got through Brexit.

"We bolster our stock holding in preparation for Brexit, but COVID came with no warming and we had the same struggles than most"

SIMON: That came with a warning. Obviously COVID didn’t. How did you get on with that?

WAYNE: Same struggles as most… In that fortunate position with the stock in place, we could maintain that level as we got through Brexit. Then as COVID hit, we had a three-month shutdown, same as the rest of the country. We came back from that and we were manufacturing slowly to start with. We had issues with supply chain, which then forced us into a situation where we had to spot buy, meaning we had to go out there and purchase at a higher price just so we could find an alternative and had continuity of supply for our customers.

SIMON: But it sounds like with careful planning you managed to navigate many of the problems that were thrown at you over the last 2 to 3 years…

LEE: Because this is an interactive tour, we asked people on social media if they had any questions. We received lots of questions through Instagram and Twitter and these are some of them…

Is there a standardised system to colour coding your looms, not just in a Bailey caravan but across the industry or across other industries?

WAYNE: To answer the questions truthfully, no, there isn’t. But within our customer base we’ve got all our customers using the same colour charts. For example, if we have an engineer that is trying to fix the flush of a toilet, they will be looking for a purple and white wire. So whichever caravan he looks for, if it has a BCA harness, the colour coding will be the same.

LEE: Talking about the green credentials of manufacturing, is any of the cables or associated parts if the loom, made of recycled materials?

WAYNE: Unfortunately, copper can not be recycled or made of recycled materials. It needs to be virgin.

SIMON: And what about the plastics?

WAYNE: There are certain elements of plastics that can be made of recycled materials. Maybe it’s a heat cover of some sort, then there’s a certain amount of regrind but it’s only a small percentage that can be used. When you’re looking at external battery boxes or locker doors, etc, they need to come with some UV protection in them. And that lends itself again to virgin material. But there are certain elements that can be made of recycled materials when they are more “hidden”, like a heat cover for example.

SIMON: That’s in terms of the product but I know that as a business, you’ve been making big strides to reduce the environment impact of your operations…

WAYNE: Yes. A big one is our returnable packaging. The pallet tubs that we use, for example. We have enough to be able to fill them here for delivery using our own transport and collect the empties when we make our delivery.

"There are plans in place to introduce lighter wiring systems similar to what you see in cars to help reduce the weight of the caravans"

LEE: We have had two separate questions both pointing to similar topics in regards to future proofing and as people tastes and wants change in a caravan. For example they might want more tech or facilities…

Are there any plans in place to a. try to factor in things that might need pre-installing wiring and b. is there anything on the horizon that could reduce weight in the loom?

WAYNE: Yes. For example over that last five years or so we’ve seen the introduction of USB sockets into most product ranges. The next would be USBC, and we’re on with that project already.

Then WI-FI in the vehicles is becoming more prevalent. Some manufacturers are fitting it already and we are feeding the power source to it.

There’s a big push to make the caravans lighter in weight if possible. So currently you have a harness that fits all the way around the vehicle. There are plans in place to introduce a limbus system very similar to what you have in your car. The idea would be that you have three wires that run around the full length of the caravan, and you pull feeds from that.

END

Images from our day at BCA Leisure

Take a look at the gallery below to see images from our day at BCA Leisure. Hover over the information icon on each photo to read the caption.

Previous

Behind the Scenes Live Tour 2022

Next

QK Honeycomb Products